As a dentist, you want to give your patients the best care possible. That means ensuring you only use the highest quality dental instruments.

Dentists have been choosing stainless steel alloys for the material of their surgical and dental instruments for some time now. Stronger metals, like stainless steel, hold up to sterilization and many years of treating dental patients day after day. The development of stainless steel alloys has yielded numerous stainless steels with qualities and properties to make them ideal for dental instruments.

Qualities and Properties Needed in Dental Instruments

For a dental instrument to be effective, it needs to have certain properties. It’s important for you to be aware of the qualities you need in your dental instruments so that you can ensure you’re working with only the best tools. Here are some of the most important properties for dental instruments to have:

– Corrosion resistance: Dental instruments may be exposed to harsh environments, so they need to be able to resist corrosion. Instruments that have been affected by corrosion are not safe to use and need to be replaced, increasing costs for your dental practice.

– Strength and hardness: Your dental instruments need to be sufficiently strong to complete the required work. There are various strength-related factors to consider, including fatigue strength, tensile strength and hardness.

– Durability: Both corrosion resistance and strength impact how durable an instrument is. Other factors are important too, such as edge retention and resistance to wear and galling.

– Simple Maintenance Requirements: Dental instruments should be relatively easy to maintain and keep clean. This makes it easier to ensure your tools are working correctly and are safe to use.

– Sustainability: Many dentists are looking to reduce their practice’s impact on the environment, and many patients feel environmental responsibility is important. For these reasons, dental instruments that are recyclable, last a long time and otherwise reduce environmental impact are ideal.

Common Materials Used in Dental Instruments

What are dental tools made of?

Dental instruments may be made from various materials, including numerous alloys of stainless steel. Let’s look at some of the common materials used in stainless steel oral surgery instruments:

1. Stainless Steel (Inox)

Standard instruments are made with the highest quality materials — they’re made with austenitic 316 steel, also referred to as surgical steel or marine-grade surgical steel. Stainless steel, also referred to as Inox, is highly resistant to corrosion and is a common material used for body piercing jewelry and biomedical implants. It’s ASTM F138 compliant. This WPI line is an excellent alternative to German surgical instruments.

The cost of stainless steel instruments that are corrosion-resistant and high-quality is much less than that of German surgical instruments also made from the same type of steel. And, stainless steel works great for medical purposes since this magnetic, stainless steel alloy has great salt and corrosion resistance. Inox is almost as strong as carbon steel and is an ideal general-purpose alloy for surgical tools.

2. Dumoxel

Dumoxel is extremely resistant to hydrochloric acid, sulfuric environments and organic and mineral acids. It’s very flexible and is stain-resistant, temperature-resistant and anti-magnetic. It’s a popular alloy for tools. Dumoxel is less magnetic and slightly softer than stainless steel.

3. Titanium

Titanium alloys are lightweight, strong, corrosion-resistant and anti-magnetic. They’re suitable for medical and biological applications. These alloys have carbon steel’s tensile strength and are resistant to corrosion caused by chloride, nitric acid, organic and industrial chemicals and saltwater. Titanium is lighter and more flexible than Inox. When it’s heated and cooled, its dimensions change less than that of stainless steel alloys, which makes Titanium dental instruments more durable. It’s temperature-resistant and stain-free. It’s the ideal choice for corrosive environments.

4. Dumostar

Dumostar is resistant to organic and mineral acids and to salt corrosion. It’s temperature-resistant and anti-magnetic, resists metal fatigue and can be elastic. It’s also an appropriate alloy for lab tools and is cost-effective.

Why Are Surgical Instruments Made From Stainless Steel?

What is the best metal for dental instruments? As a dentist, you want to provide your patients with nothing but outstanding treatment. However, you can undermine the quality of your treatment by using low-quality dental tools and instruments. So, it’s essential that you use only high-quality stainless steel dental instruments.

Why are oral surgical instruments made of stainless steel? Here are some advantages of using stainless steel instruments and why they’re the best choice.

1. Durability and Strength

Stainless steel performs much better than cheaper materials like chrome-plated metals, plastic or brass. These materials are more likely to peel, chip or become damaged by heat and chemicals used in the sterilization of stainless steel instruments. The durability of stainless steel dental instruments enables them to stand up to the demands of sterilization.

There are different strengths of stainless steel dental instruments. Dental instruments made today often are required to be longer and thinner, requiring materials with higher:

– Fatigue strength

– Toughness

– Tensile strength

These are all interrelated properties. Typically, as the hardness and strength of stainless steel dental instruments increase, the ductility decreases. This differs, however, among alloy families.

2. Edge Retention, Wear Resistance and Galling Resistance

Edge retention is a crucial material property for shaping and cutting instruments. If a cutting edge gets prematurely dull, the instrument becomes difficult and possibly dangerous to handle. Stainless steel is a stronger metal, so if you sharpen stainless steel dental instruments, you know they’ll retain their sharp edge.

Galling and wear resistance are critical for moving metallic components. If galling or wear develops in service, the device will stop working correctly and could introduce metallic particles into a wound. The hardening method and hardness of a material determine its wear resistance and edge retention. Usually, as the metal’s hardness increases, so do the wear resistance, edge retention and galling resistance. Stainless steel has excellent hardness and therefore provides superior wear resistance, edge retention and galling resistance.

3. Corrosion Resistance

Why choose stainless steel dental instruments? One reason is their excellent corrosion resistance. Stainless steel is popular for its resistance to corrosion, even in environments where carbon and low alloy steels would corrode. Its corrosion resistance is due to the extremely thin oxide layer on the steel’s surface.

The grade of stainless steel determines the extent of its corrosion resistance. Typically, the higher the chromium content, the more resistance to corrosion the metal has. For this reason, medical grade stainless steel is the preferred, safe and corrosion-resistant material for dental instruments. Stainless steel dental instruments also perform better over the long term when compared to inexpensive materials like brass, plastic and other chrome-plated materials.

While stainless steel has superior corrosion resistance properties, it can corrode or discolor if exposed to certain chemicals, such as household bleach or tartaric acid.

4. Favorable Strength-to-Weight Ratio

Another notable benefit of stainless steel dental instruments is the substantial strength-to-weight advantage over other materials. Due to its unique ability to resist heat damage, corrosion and chemical damage, the higher strength duplex grades offer extra strength, enabling for a decreased material thickness. This feature reduces costs as compared to other materials.

5. Easy Maintenance and Sanitization

Stainless steel doesn’t have any inherent anti-microbial properties like copper and other metals do, but you can clean it easily with sanitizing solutions. Dental instrument manufacturers now offer a modern coating consisting of micelles that can be applied to stainless steel during production. This process provides stainless steel with enhanced bacteria resistance.

6. Sustainability

Stainless steel is reusable and recyclable, which helps to reduce waste and environmental impact. With nearly 90% of end-of-cycle Stainless Steel being recycled, using stainless steel dental instruments can help make your practice greener, which is excellent for both the planet and your business’ reputation.

Types of Stainless Steel Appropriate for Dental and Oral Surgery Instruments

Which stainless steel is best suited for surgical instruments? Manufacturers most commonly use two types of stainless steel series for stainless steel medical instrument manufacturing.

– Austenitic (300 series) stainless steel: Heat treatment can’t harden Austenitic steel. The 304 grade is often the grade used for surgical instruments. It works well for items requiring some malleability, meaning they can be formed or pressed into another shape without the metal breaking. The instruments traditionally made with this steel series are probes, retractors, cannulas, spreaders and mallets.

– Martensitic (400 series) stainless steel: Martensitic steel is low carbon steel that heat treatment processes can harden and temper. This steel series is ideal for instruments that require strength and tough cutting edges. Instruments traditionally made using the 410 – 420 grades of this steel series are scissors, extraction forceps, elevators, and working ends of scalers, chisels, and many other instruments.

Stainless steels are engineering materials that have great strength, corrosion resistance and fabrication characteristics. There are different grades of stainless steel for dental instruments.

While we can’t list them all here, some types of stainless steel that are suitable for dental surgery instruments are:

– Type 201: A grade that isn’t as corrosion-resistant as the 300 series. It provides a higher yield strength.

– Type 301: A grade that has outstanding corrosion resistance, ductility and high strength.

– Type 302: A grade that resists oxidation, is easy to clean, offers easy fabrication and has a low weight with high strength.

– Type 304: A grade (304L) that serves a large range of applications. It resists dyestuffs, organic chemicals and a large variety of inorganic chemicals.

– Type 305: A grade that provides high strength-to-weight ratio, low work hardening, is easy to clean and fabricate, has an attractive finish and is outstanding for cold heading and free spinning.

– Type 308: A grade that has increased corrosion and oxidation resistance as compared to type 305, excellent heat resistance, high ductility, and extremely good weldability.

– Type 309: A grade with high-temperature strength that is easy to weld.

– Type 316: A grade that has a little bit more nickel than type 304, which provides it with better corrosion resistance than type 304, particularly in chloride environments. The 316L grade also has great intergranular corrosion resistance after stress relieving or welding. It is simple to maintain, superior creep strength, good pitting resistance and close tolerances.

– Type 405: A grade that has good ductility, easily machines, has good corrosion resistance, resists oxidation and is easily formed.

– Type 409: A grade that has extremely low alloy content and is used for applications that require corrosion resistance and strength.

– Type 410: A grade that is heat and corrosion resistant, is easily welded, resists scaling, resists oxidation and offers high impact strength.

– Type 420: A grade that’s very durable, offers outstanding hardening to 500 BHN and is corrosion-resistant. Generally used for surgical instruments and dental instruments.

– Type 430: A grade that has less alloy content than 304. It has great ductility, formability and corrosion resistance, thermal conductivity, and oxidation resistance. It has low work hardening and offers an attractive finish.

– Type 440A: A corrosion-resistant martensitic grade of stainless steel containing chromium that offers a large range of mechanical properties through the process of heat treatment. This grade provides excellent wear resistance of high carbon steel with stainless steel’s corrosion resistance.

The Stainless Steel That ProDentUSA Uses

A single instrument’s journey begins from the moment we obtain raw 440A stainless steel at our manufacturing facility in Pakistan. From there, each instrument is crafted meticulously and carefully to fulfill its mission.

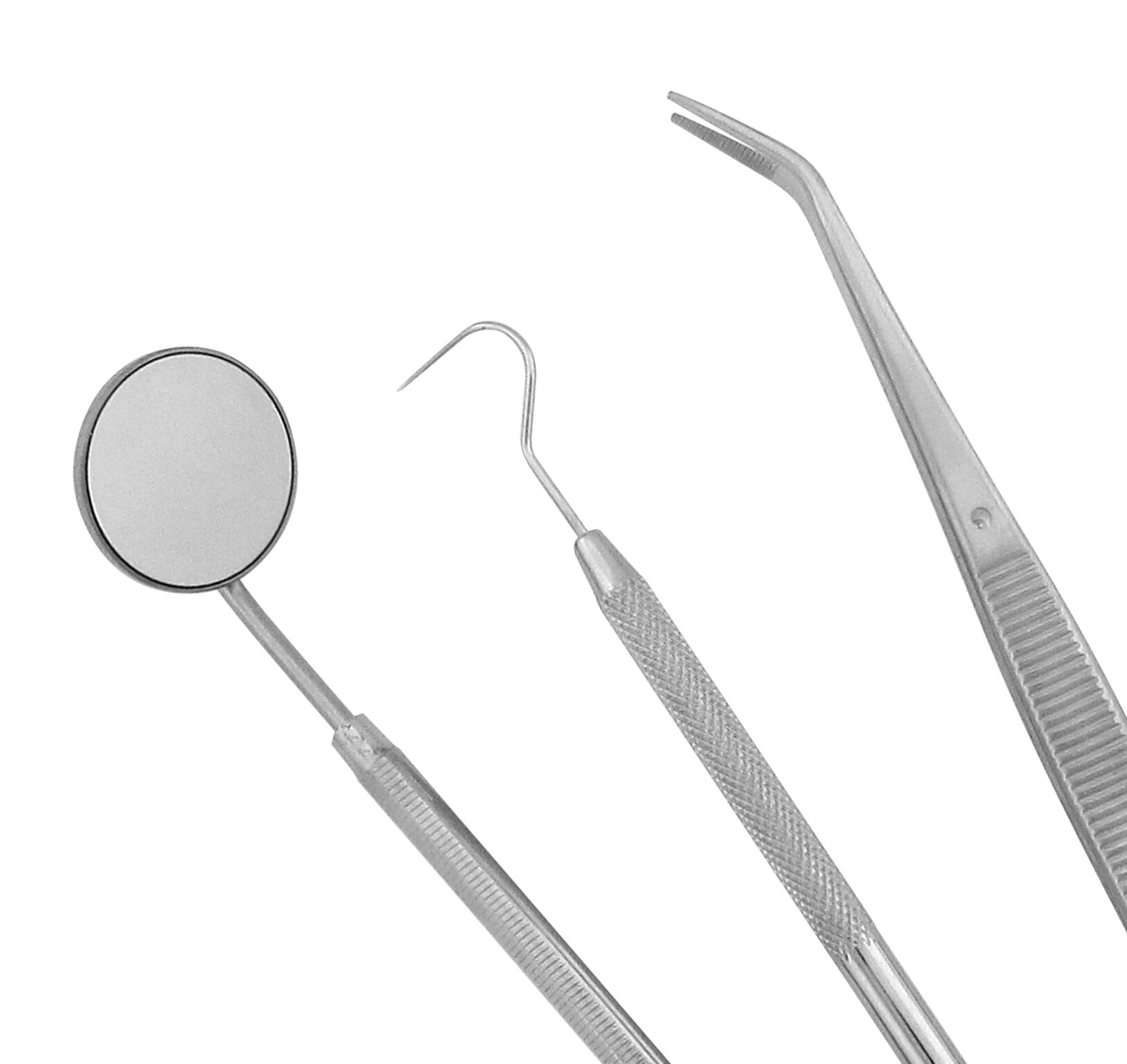

Our diagnostic dental instruments include:

– Mirrors: Our dental mirrors are long-lasting and come in various sizes, so they adapt easily to various applications.

– Probes: Our dental probes are made with black titanium that’s chip-and-crack resistant and come in various markings for charting precisely.

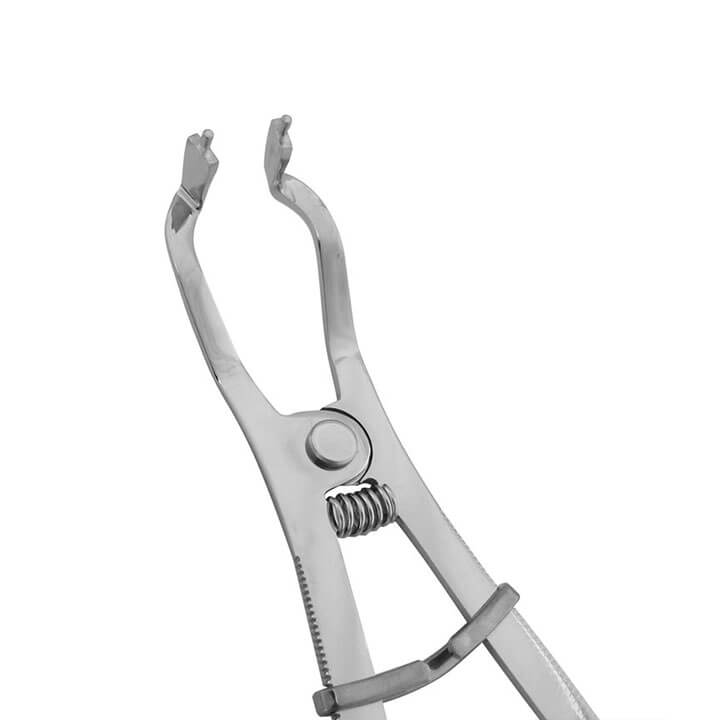

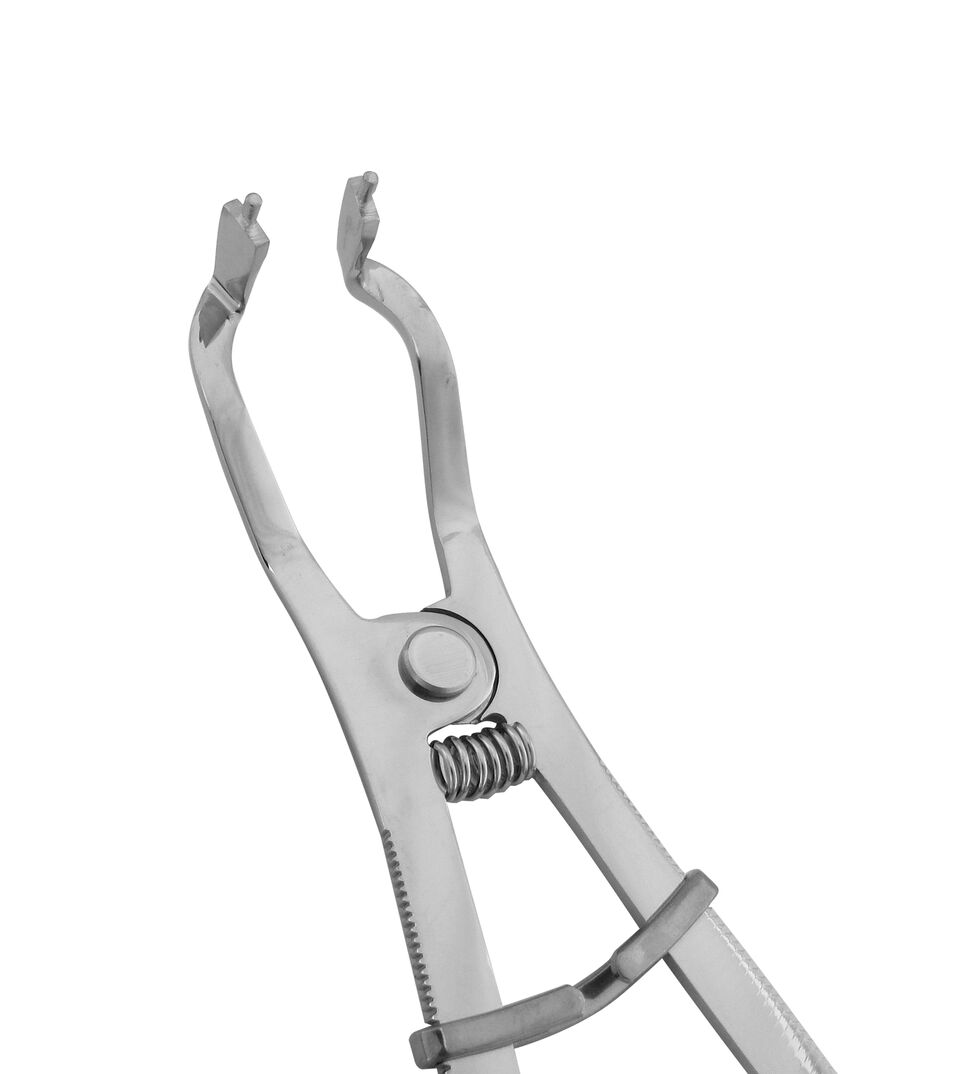

– Pliers: Our dental pliers are forged from non-magnet, resilient stainless steel, offering various sizes and working ends that adapt to all applications.

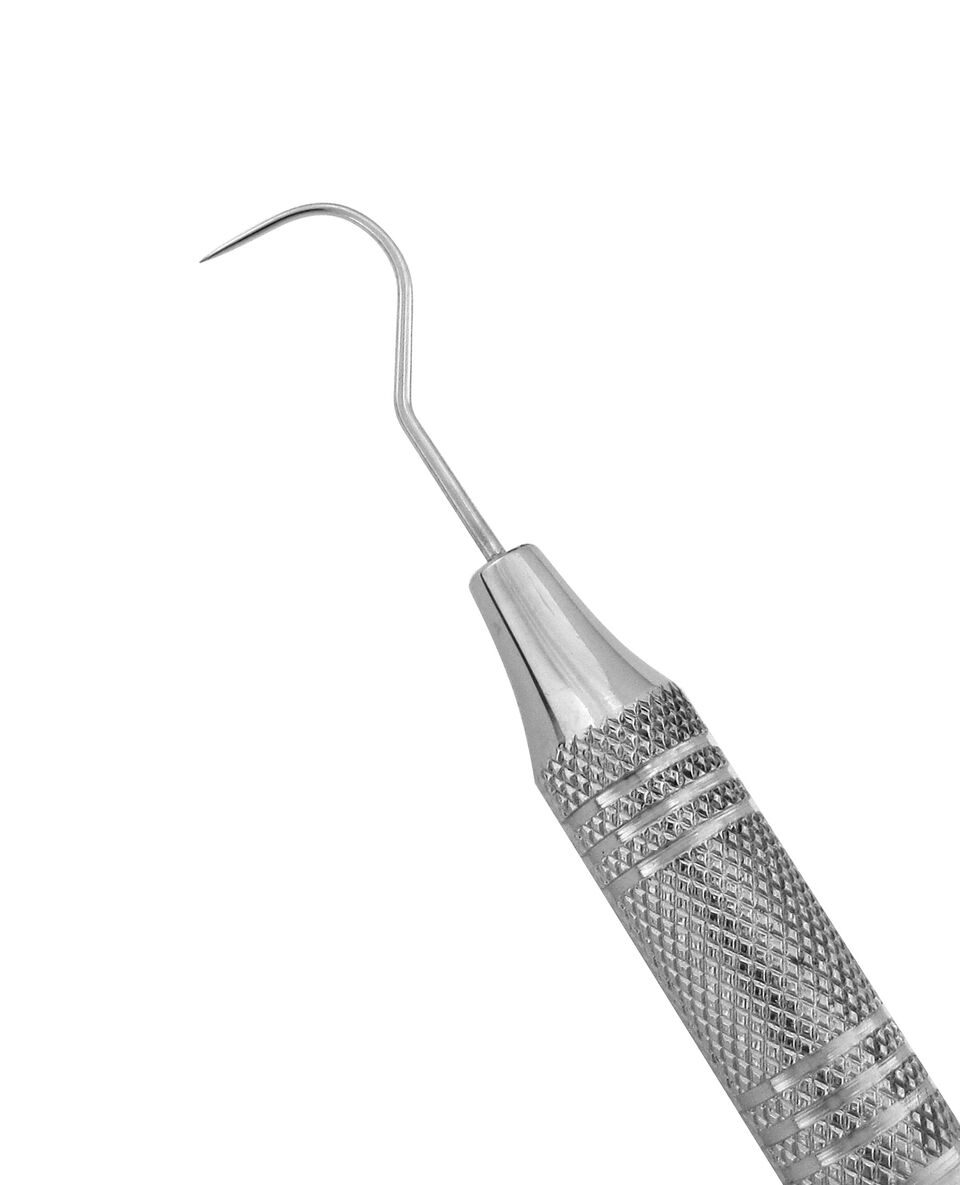

– Explorers: Our dental explorers are hand-crafted from French spring steel and provide the enduring precision and flexibility needed for accurate diagnosis and careful exploration.

– Intraoral photography mirrors: Created from Grade A stainless steel, our intraoral photography mirrors are great for dental photography.

– Diagnostic sets and accessories: At ProDentUSA, you’ll find everything you need for diagnostics in one place. We efficiently assemble our instruments in sleek, convenient diagnostic and accessories sets.

Choose ProDentUSA for Your Stainless Steel Dental Instrument Needs

We get to know our materials, staff members and practitioners so we can deliver the absolute best products. Our premium dental instruments are meticulously crafted to offer your patients the best quality patient care. Our stainless steel dental instruments will help you keep your patients’ smiles healthy, without compromising quality or fairness at any step along the way. View our extensive product selection to learn more.

Diagnostic Sets & Accessories

Diagnostic Sets & Accessories Dressing Pliers

Dressing Pliers Explorer/Probes

Explorer/Probes Explorers

Explorers Intraoral Photography Mirrors

Intraoral Photography Mirrors Mirror Handles

Mirror Handles Mirrors

Mirrors Probes

Probes Endo Excavators

Endo Excavators Endo Explorers

Endo Explorers Endo Forceps

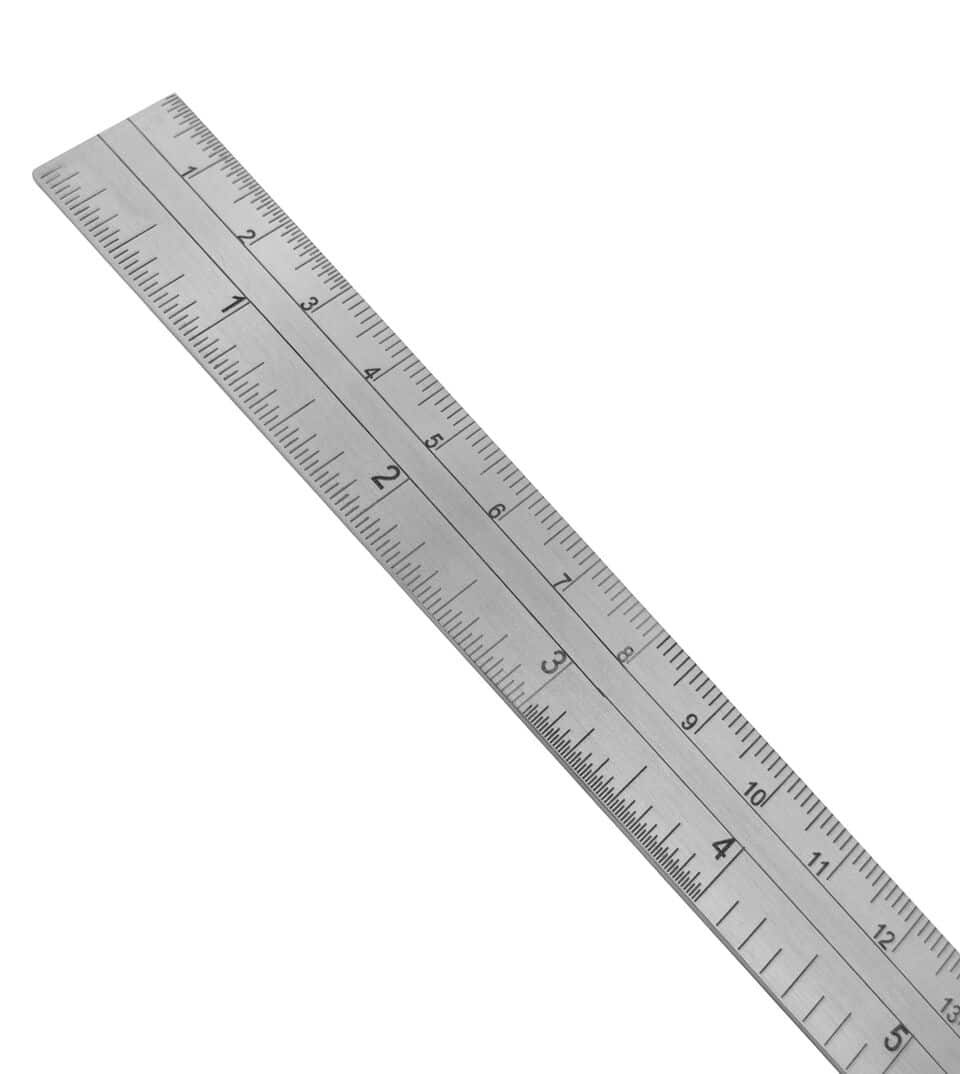

Endo Forceps Endo Rulers

Endo Rulers Endodontic Sets

Endodontic Sets Root Canal Pluggers

Root Canal Pluggers Root Canal Spreaders

Root Canal Spreaders Rubber Dam Clamps

Rubber Dam Clamps Rubber Dam Frames

Rubber Dam Frames Rubber Dam Punches & Forceps

Rubber Dam Punches & Forceps Cutters

Cutters Elastic Placing Mathieu Pliers

Elastic Placing Mathieu Pliers Gauges

Gauges Hand Instruments

Hand Instruments Mosquitoes

Mosquitoes Orthodontic Sets

Orthodontic Sets Pliers

Pliers Scissors

Scissors Tweezers

Tweezers Curettes

Curettes Gracey Curettes

Gracey Curettes Periodontal Sets & Accessories

Periodontal Sets & Accessories Periodontal Specialty Instruments

Periodontal Specialty Instruments Scalers

Scalers Siberian Stone™ Collection

Siberian Stone™ Collection Amalgam Carriers & Well

Amalgam Carriers & Well Burnishers

Burnishers Calipers

Calipers Carvers

Carvers Cement Spatulas

Cement Spatulas Chisels

Chisels Composite & Plastic Filling Instruments

Composite & Plastic Filling Instruments Crown Removers & Spreaders

Crown Removers & Spreaders Excavators

Excavators Forceps & Tweezers

Forceps & Tweezers Gingival Cord Packers

Gingival Cord Packers Gingival Retractors

Gingival Retractors Hatchets

Hatchets Impression Tray Sets

Impression Tray Sets Margin Trimmers

Margin Trimmers Matrix Retainers

Matrix Retainers Placement Instruments

Placement Instruments Plaster Knives & Nippers

Plaster Knives & Nippers Plaster Spatulas

Plaster Spatulas Pluggers/Condensers

Pluggers/Condensers Restorative Sets

Restorative Sets Wax & Porcelain Carvers

Wax & Porcelain Carvers Wax Spatulas

Wax Spatulas Waxing Instruments

Waxing Instruments Aspirators

Aspirators Bone Chisels

Bone Chisels Bone Grafting Instruments

Bone Grafting Instruments Calipers

Calipers Clamps

Clamps Dental Elevators

Dental Elevators Extraction Forceps

Extraction Forceps Hemostats & Forceps

Hemostats & Forceps Hybrid Instruments

Hybrid Instruments Implant Instruments

Implant Instruments Luxating Elevators

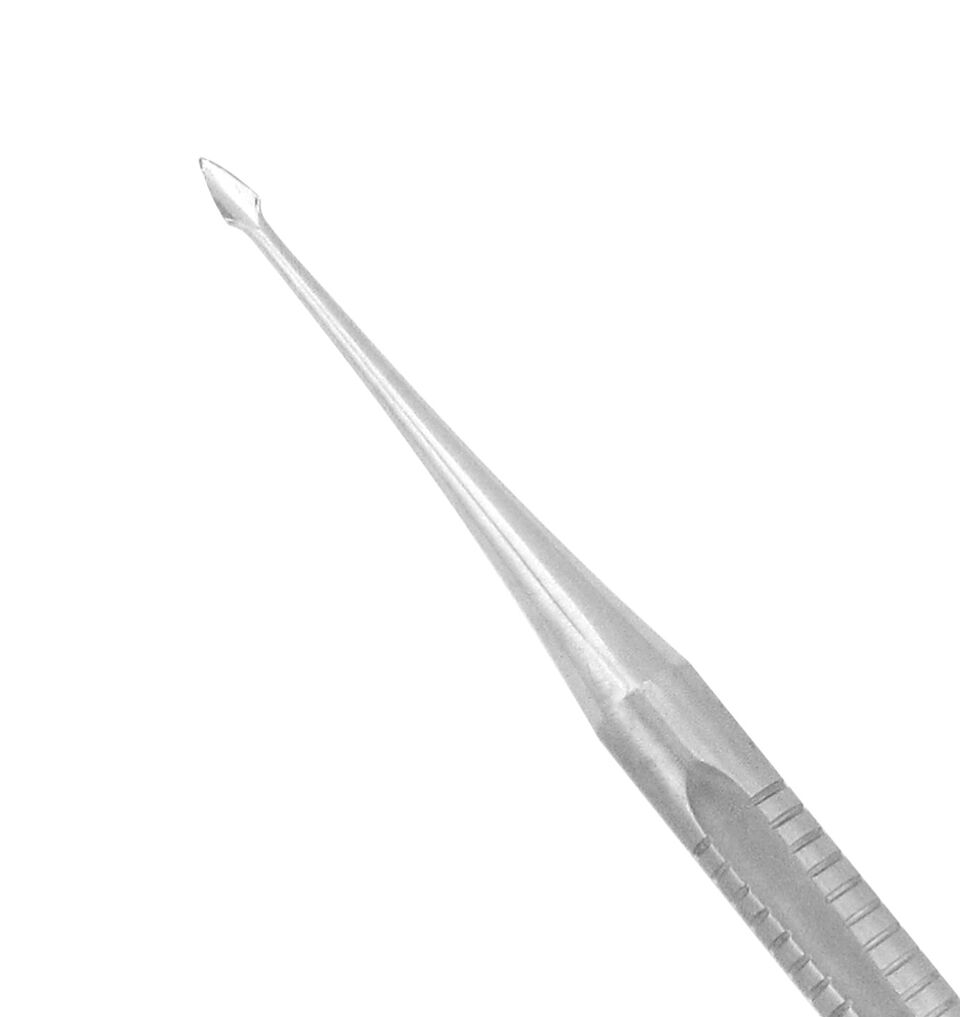

Luxating Elevators Mouth Gags & Retractors

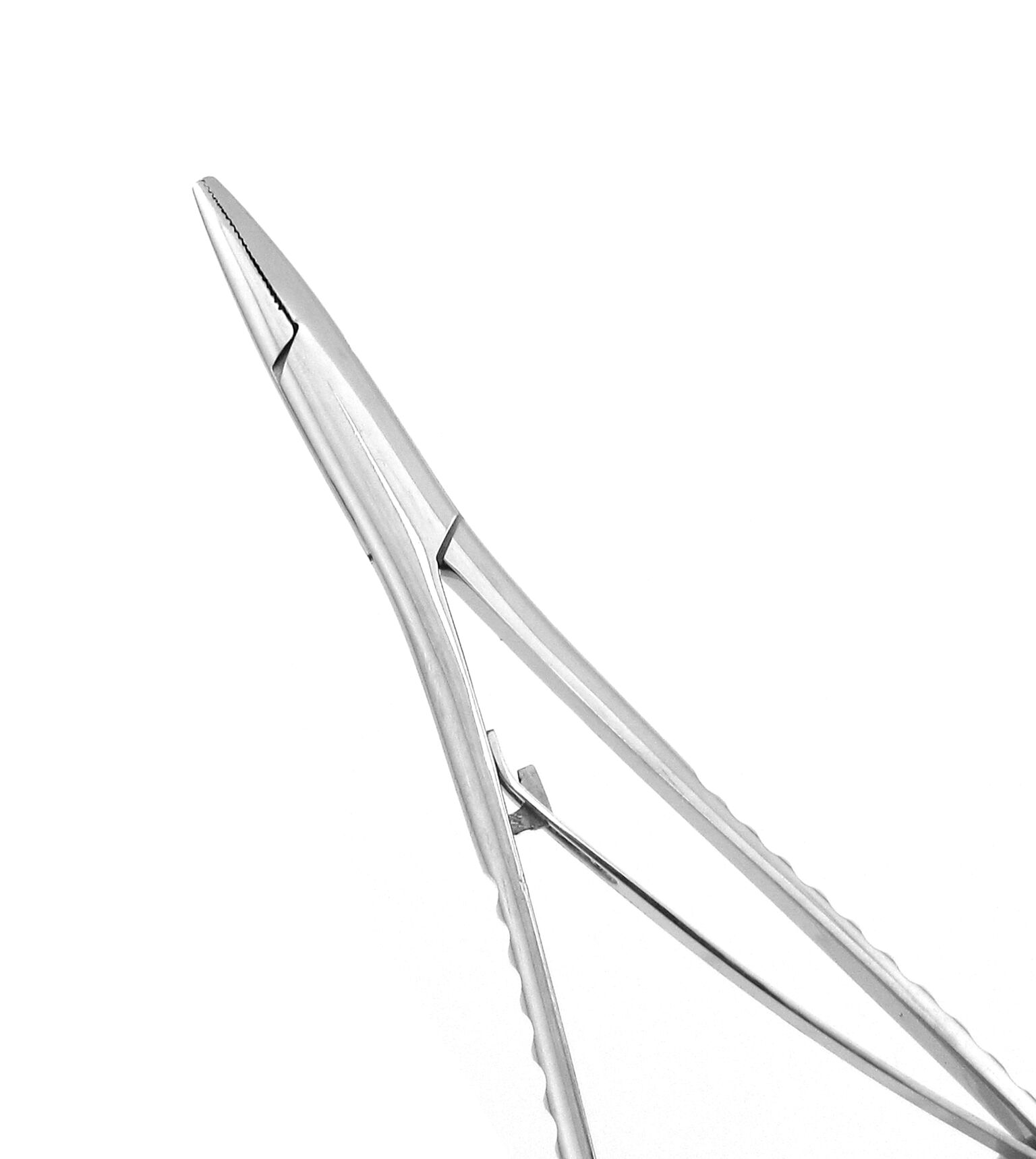

Mouth Gags & Retractors Needle Holders

Needle Holders Oral Surgery Aspirating Syringes

Oral Surgery Aspirating Syringes Periodontal Surgical Instruments

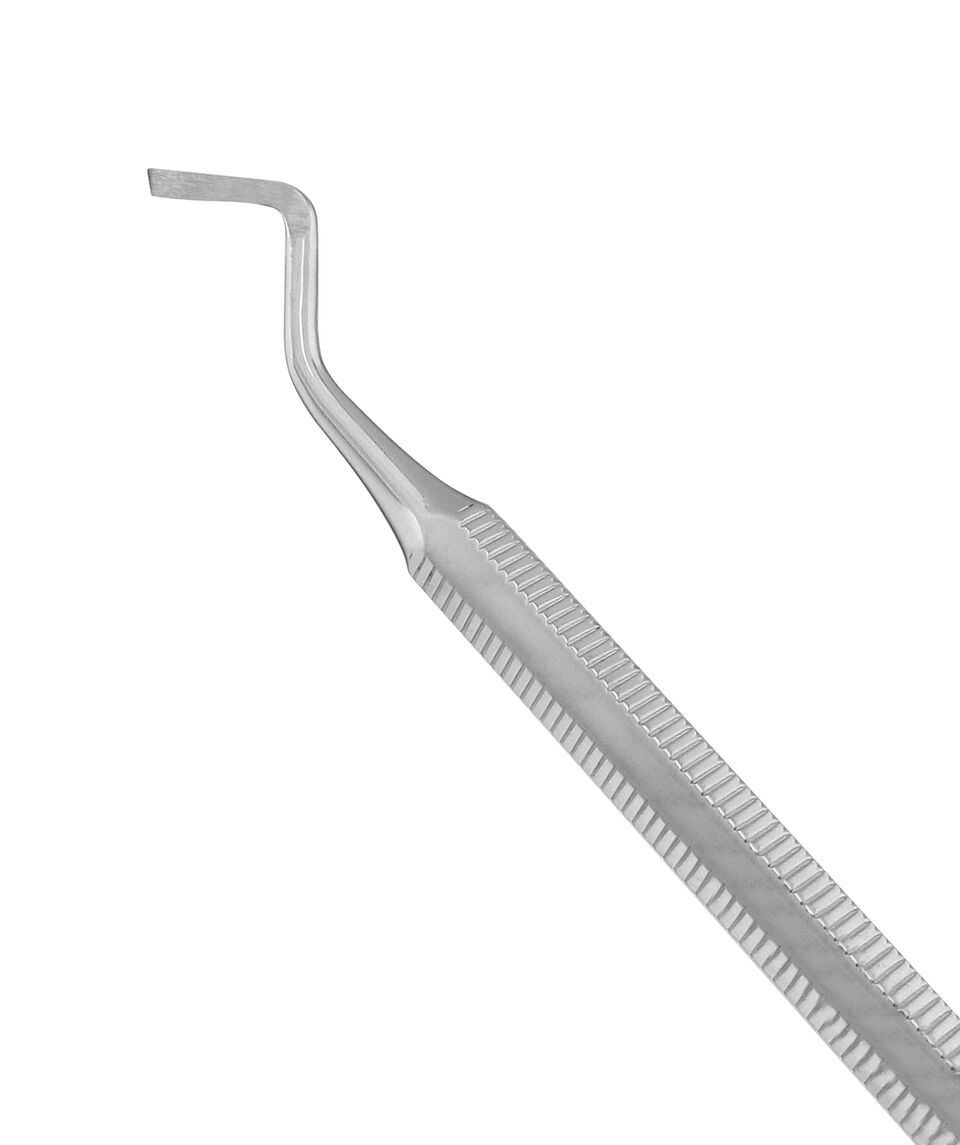

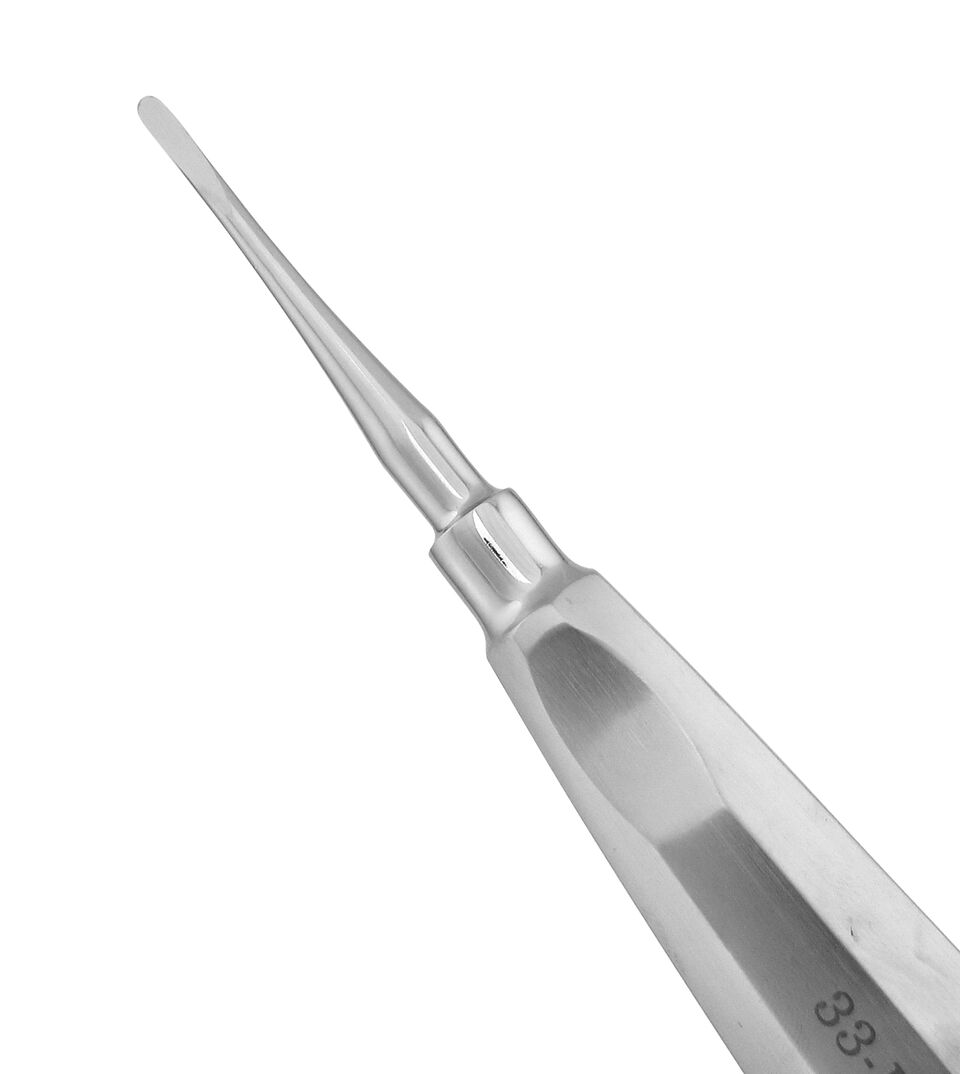

Periodontal Surgical Instruments Periosteal Elevators

Periosteal Elevators Periotomes

Periotomes Rongeurs

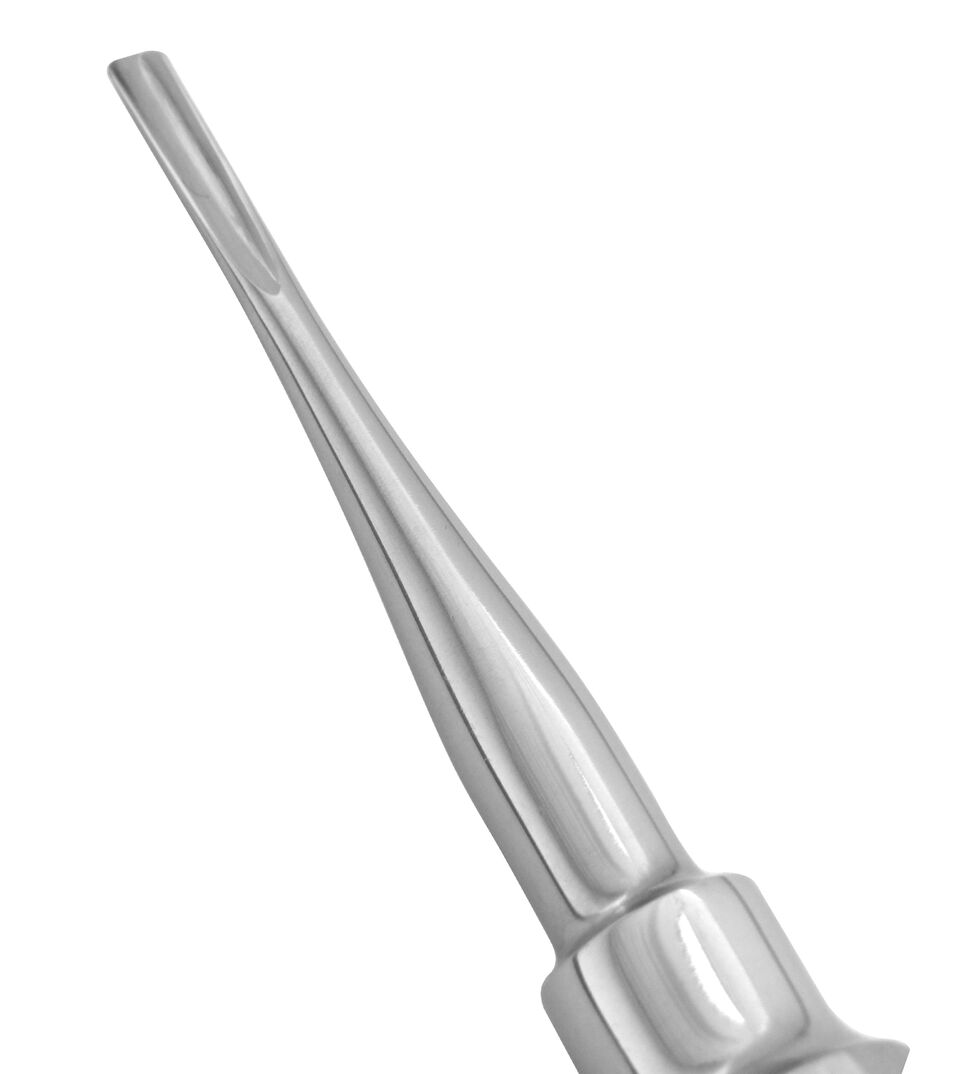

Rongeurs Scalpel Handles

Scalpel Handles Surgical Curettes

Surgical Curettes Surgical Pediatric Forceps

Surgical Pediatric Forceps Surgical Sets

Surgical Sets Suture Forceps

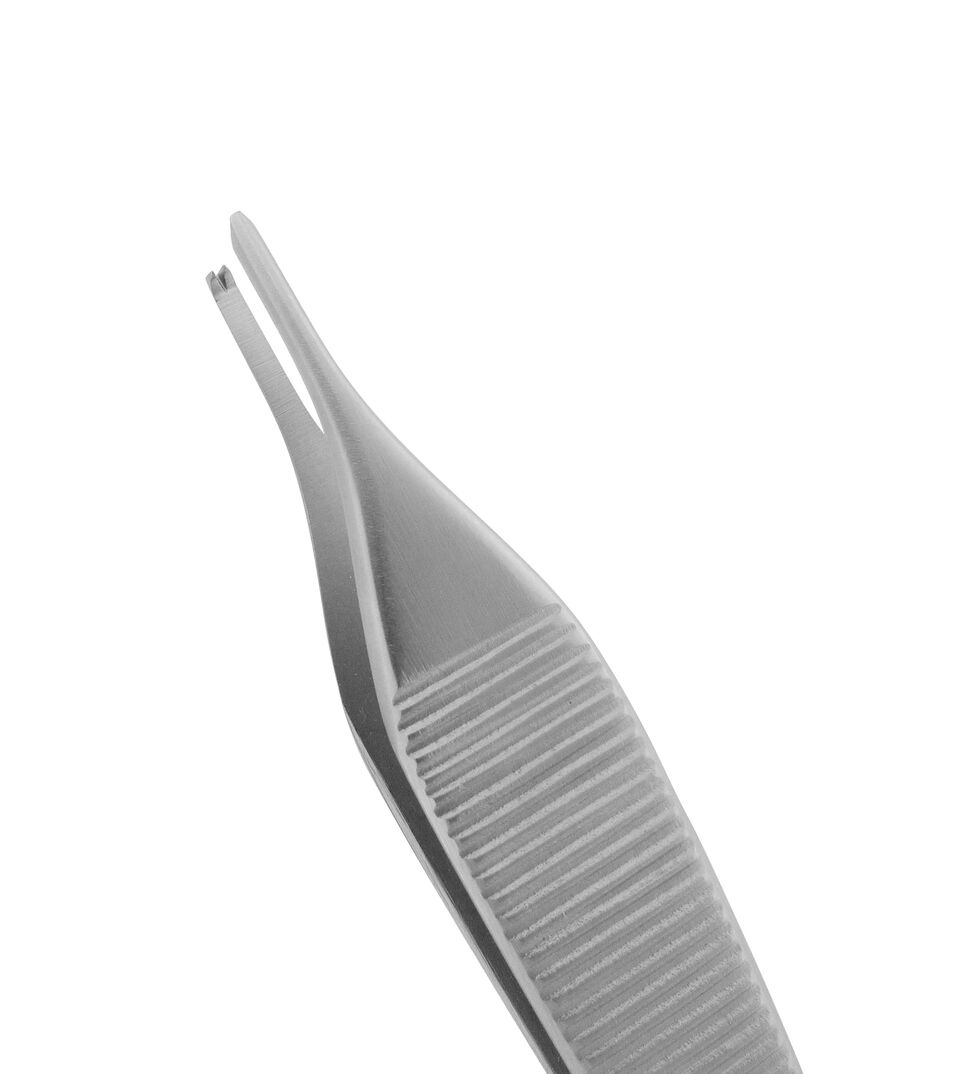

Suture Forceps Tissue & Dressing Forceps

Tissue & Dressing Forceps Utility Forceps

Utility Forceps Stainless Steel Crowns

Stainless Steel Crowns Personal Protective Equipment

Personal Protective Equipment